基金项目:中央引导地方科技发展专项资金资助项目(2020 JH 6/10500016)。

作者简介:陈诗瑶(1996—),女,辽宁葫芦岛人,硕士研究生。主要从事机械设计及理论领域的研究工作。

(1.沈阳工业大学 机械工程学院,沈阳 110870; 2.中国中化锦西化工研究院有限公司,辽宁 葫芦岛 125000)

(1.School ofMechanical Engineering, Shenyang University of Technology, Shenyang 110870, China; 2.Jinxi Research Institute of Chemical Industry Co Ltd, Sinochem Holdings, Huludao 125000, China)

composite system; nitrile rubber; polyvinyl chloride; single walled carbon nanotubes; blend; elastic modulus; wear resistance

目前,国内主要采用丁腈橡胶(NBR)作为螺杆泵定子衬套的材料,其耐油性极好,耐磨性较高,耐热性和耐老化性能较好,但其强度与模量低,且实际采油工况较为复杂,除了要选择合理的定子橡胶材料外,还要在橡胶材料的改进上进行深入的研究,以此提高潜油螺杆泵的使用寿命。聚氯乙烯(PVC)具有良好的耐磨性、阻燃性、抗化学腐蚀性、较高的机械强度,成本低廉且易得,此外,NBR和PVC都是极性聚合物,二者的溶解度参数非常接近(NBR和PVC的溶解度参数分别为9.64和9.60)[1],相容性较好,NBR/PVC复合材料的制备过程相对容易。刘霞[2]向NBR与PVC回收料的共混胶中加入马来酸酐增容剂,结果发现共混胶的力学性能有所提升;严海彪等[3]研究了白炭黑、轻质碳酸钙、高耐磨炭黑对NBR/PVC共混胶力学性能、耐热老化性、耐油性等性能的影响,结果发现高耐磨炭黑的增强效果最好;王刚[4]研究发现当NBR与PVC的配比为60/40~70/30(质量比,下同)时NBR/PVC共混胶的性能较好,而当NBR中结合丙烯腈质量分数为39%时NBR/PVC共混胶的性能最佳;曹沛等[5]研究发现橡塑并用配比为70/30时性能最好,硫化体系使用低硫高促体系,填料选用碳酸钙,其用量越大则复合材料的密度越高。

近些年来,纳米材料的应用越来越广泛,碳纳米管的力学性能和化学性能也优于其他增强材料,其中,单壁碳纳米管(SWCNTs)具有极强的吸附性能、优异的储氢性能和较大的比表面积,且无层间交互作用,其力学性能非常优异,相当于钢的100倍。

本工作选用SWCNTs作为增强材料以增强NBR/PVC复合体系,采用分子动力学(MD)模拟的方法从原子角度去计算和分析材料的力学性能和摩擦学性能。该方法能在纳米尺度上非常精确地模拟大量分子组成的复杂体系,并可获得一定条件下的平衡结构,同时根据牛顿力学的基本原理,模拟分子间的相互作用和粒子的运动轨迹,再使用统计学方法分析运动轨迹数据,提高研究的效率与精确性,从而达到降低实验成本的目的。

NBR是由丁二烯(BD)和丙烯腈(AN)两种单体聚合而成的共聚物,本工作选用AN单体质量分数为39%。由于分子链过长会导致计算误差过大、模拟的精确度降低[6],为了得到合理的结果,本工作分别构建了含有30个重复单元的NBR和PVC分子链,然后建立1个周期性立方晶格,其长度适中,通常大于3 nm,否则容纳的原子数太少,同时长度也不能过大,因此,本工作选用周期性立方晶格的长度为4 nm,将NBR与PVC以70/30的质量比填充到晶格中(如图1所示)。

Li等[7]研究发现直径为0.678,0.814 nm的碳纳米管增强效果较好。为了进一步研究SWCNTs的增强效果,本工作使用Build分别构建直径为0.678,0.814,0.949 nm的SWCNTs,同时为防止SWCNTs与晶格的相互作用,将SWCNT长度设为2.951 nm,其基本信息列于表1,其中,(N,M)代表SWCNT的手性指数,N为SWCNTs整体尺度的控制指数,M为构建SWCNTs石墨片手性角度的控制指数;然后创建SWCNTs的质心,并将其放至晶格中心,选用Amorphous Cell模块的Packing任务,在长度为4 nm的周期性立方晶格中构建不同直径SWCNTs增强NBR/PVC复合体系的无定形分子模型。将构建的4种复合体系NBR/PVC、NBR/PVC/SWCNTs(5,5)、NBR/PVC/SWCNTs(6,6)、NBR/PVC/SWCNTs(7,7)分别编号为1、2、3、4(如表2所示)。

为了获得最低能量结构,选择Forcite Plus模块中的Geometry Optimization任务、采用共轭梯度法对NBR/PVC复合体系进行结构优化。当相邻两个迭代步之间的能量差值小于设定的收敛公差时,表明该体系达到了平衡,然后分别选择正则系综和等温等压系综分别在温度298 K、压力0.1 MPa下进行600 ps的MD平衡;为充分利用计算时间,选择时间步长为1 fs。计算过程中分别选用Andersen算法[8]和Berendsen算法[9]保持体系的温度与压力恒定,选用Ewald求和方法来计算周期系统中的非键能量,选用Atom based方法[10]来计算范德华力,以上所有操作均使用适合高分子体系的COMPASS力场。

本工作采用恒应变法对4种NBR/PVC复合体系进行力学性能的计算,应变步数为4,最大应变振幅为0.003,在xx、yy、zz、yz、zx和xy 6个方向上施加应变,应变值(ε)等于(-0.003,-0.001,0.001,0.003)。计算结束之后,可得到6×6的弹性系数矩阵Cij和弹性柔度矩阵Sij,其中i和j均为1~6的自然数。因除C11、C22、C33、C44、C55、C66、C12、C13、C23之外的弹性系数Cij的值都趋近于0,故在此不一一列出。C11、C22、C33、C44、C55、C66、C12、C13、C23具体计算结果列于表3。由表3可以看出,弹性系数C11、C22和C33,C44、C55和C66及C12、C13和C23这3组数据都相对较为接近,这表明4种NBR/PVC复合体系均为各向同性的材料。

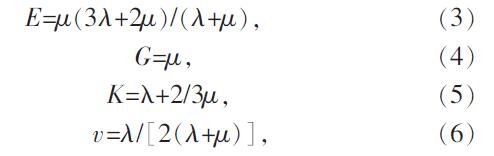

可以使用拉梅系数λ和μ[11]计算SWCNTs增强NBR/PVC复合体系的弹性模量与力学常数,具体如下:

弹性模量包括杨氏模量(E)、剪切模量(G)和体积模量(K),E越大表示材料越不容易发生形变,G越大则表示材料的刚性越强、摩擦磨损性能越好。材料的韧性为K与G的比值,即K/G;柯西压[12]为C12与C44之差值(C12-C44),可用来表示材料的脆性、硬度和延展性[13];泊松比(v)表示材料抵抗变形的能力。E、G、K及v可分别由式(3)、式(4)、式(5)及式(6)计算而得:

计算结果列于表4,其中Ex、Ey和Ez分别为x方向、y方向和z方向的E,EAvg为E的平均值。由表4可以看出,使用直径分别为0.678,0.814,0.949 nm的SWCNTs对NBR/PVC复合体系进行增强后,该复合体系的韧性分别提升了10.1%、48.4%、122.3%,柯西压分别提高了13.5%、61.5%、140.3%,v分别提高了23.1%、19.2%、42.3%。

由图2和图3可知,加入直径为0.678 nm的SWCNTs对NBR/PVC复合体系进行增强后,复合体系的弹性模量与力学性能均得到了提升,其中E、K、G分别提升了15.2%、10.8%、14.3%;但直径为0.814 nm和0.949 nm的SWCNTs对NBR/PVC复合体系进行增强后,复合体系的弹性模量均低于NBR/PVC复合体系,模量的下降使得材料的韧性有了大幅提升,而材料的抵抗变形能力则变化不大。结上所述,直径为0.678 nm的SWCNTs增强NBR/PVC复合体系的力学性能最佳。

在NBR/PVC复合体系中加入不同直径的SWCNTs进行增强之后,复合体系的硬度、韧性及抵抗变形的能力均得到了提升。这主要是由于SWCNTs本身具有很强的力学性能与界面吸附能力[14],在很大程度上增强了橡胶基体的模量,与此同时,将有更多的NBR和PVC分子链吸附在SWCNTs的表面,复合体系变得更加稳定且不易分散脱落,从而使得共混橡胶基体表面刚性增强,在受到外力作用时,表面材料不易被挤压变形,耐磨性能得以提高,进而提高了定子橡胶的使用寿命。

MSD即原子从任一时间原点起,经历一定时间间隔的平均位移,用来表示体系中粒子的扩散活动性[15]。本工作选取5 ps的时间间隔,分别对4个NBR/PVC体系中的分子链进行MSD的计算,得到MSD-时间曲线(如图4所示)。由图4可以看出,随着SWCNTs直径的不断增大,MSD逐渐减小,且其随时间的延长呈线性变化,其斜率变小,从而表明分子链越来越趋于稳定。这主要是由于SWCNTs本身具有很强的吸附作用,从而使得NBR/PVC复合体系的稳定性更强、分子链之间缠绕得更加紧密。MSD斜率越小,SWCNTs被NBR/PVC聚合物束缚的作用就越大,体系的黏度就变得越大,减阻效果亦越强[16],最终NBR/PVC复合体系的耐磨性能得以提升。

要确定NBR/PVC复合体系的摩擦性能,首先需要给该材料体系构建一个金属摩擦副模型。如图5所示,通过构建一个分层结构可定义壁面和它们之间的流体层,将上壁面设置为铁销原子层,流体层分别为4种复合体系的无定形体系,下壁面设置为铁原子层,上壁面沿正A矢量方向,下壁面沿负矢量方向,两个壁面以等值但方向相反的速度进行剪切。在剪切模拟前固定铁原子的位置,通过结构优化、正则系综动力学平衡和退火得到NBR/PVC复合体系的最优构型,然后解除对铁原子的限制,并进行450 ps的摩擦模拟。

由图5和表5可以看出,经铁销摩擦后,NBR/PVC复合体系呈现出很大的剪切变形效应,分子链出现了明显的断裂现象,体系逐渐分散,稳定性较低,表面材料沿着剪切的方向逐渐脱落;而直径为0.678 nm的SWCNTs增强NBR/PVC复合体系在摩擦过程中橡胶基体紧紧围绕在SWCNTs的周围,有效地抵抗了铁销的剪切作用,使得分子链排列非常紧密。这主要是因为经过SWCNTs增强后,橡胶分子链的运动空间受到了限制,在受到外力作用时发生的变形就会减小,表面材料脱落减少,而且SWCNTs本身具有很强的吸附能力[17],这就使得分子链被紧紧地吸附在SWCNTs的表面,而SWCNTs又具有较高的比表面积,可以吸附更多的分子链,复合体系整体变得更加稳定,不易分散脱落,抗金属摩擦能力亦随之变强。此外,由表5还可以看出,NBR/PVC复合体系经过SWCNTs加以增强后,其磨损量与摩擦系数均得到了一定程度的下降,经过直径为0.814,0.949 nm的SWCNTs增强后的NBR/PVC复合体系的耐磨性能并没有直径为0.678 nm的SWCNTs增强NBR/PVC复合体系的好,这很有可能是因为直径过大的SWCNTs在复合体系中分布不均匀、应力不集中,而且在使用共轭梯度法进行优化时,均出现了局域势阱的现象。

RDF描述了所研究粒子周围其他粒子在空间内的分布概率,通常用g(r)来表示,其中r为粒子之间的距离。对于有序的晶体结构,g(r)有长程的峰,峰高且尖,表示有序性强,原子之间的联系比较紧密,一般在晶胞边长一半的范围内考察RDF。由图6可以看出,NBR/PVC复合体系不存在分子内的作用力,分子间g(r)的氢键作用范围为0.26~0.31 nm,范德华力作用的范围为0.31~0.50 nm,当其范围超过0.50 nm时范德华力的作用就出现减弱的现象。第1个峰值小于0.30 nm,这表明复合体系为无定形结构,其分子间的主要作用方式为范德华力,各组分之间的结合也是源于范德华力的作用。随着r的增大,加入SWCNTs进行增强后,NBR/PVC复合体系的g(r)降低,这表示铁销周围的碳原子数量变少,即在金属的摩擦作用下,橡胶基体表面材料脱落的数量变少,磨损量下降。这主要是因为在加入SWCNTs后,由于表面存在范德华力与静电力作用[17],SWCNTs可以对橡胶分子链起到黏着吸附的效果,且其本身就具有极强的吸附能力,使得大量的分子链缠绕在SWCNTs的外表面,NBR/PVC复合体系变得更加紧密,橡胶基体的刚性与稳定性增强,减少了表面材料因受到金属摩擦而发生的脱落现象,最终耐磨性能得到了一定程度的提升。

a)加入SWCNTs后,NBR/PVC复合体系的刚性变强,硬度变大,力学性能得到提升。其中,NBR/PVC复合体系经直径为0.678 nm的SWCNTs增强后,其E、K、G、韧性、柯西压和v分别提升了15.2%、10.8%、14.3%、10.1%、13.5%和23.1%。

b)NBR/PVC复合体系经直径为0.678 nm的SWCNTs增强后,其磨损量减少了46.77%,耐磨性能得以大幅度提升。

c)由于SWCNTs表面存在的范德华力与静电力作用对分子链具有黏着吸附的效果,从而使得橡胶基体更加稳定,在受到外界摩擦磨损时不易脱落,耐磨性能有所提升,进而延长了定子橡胶的使用寿命。